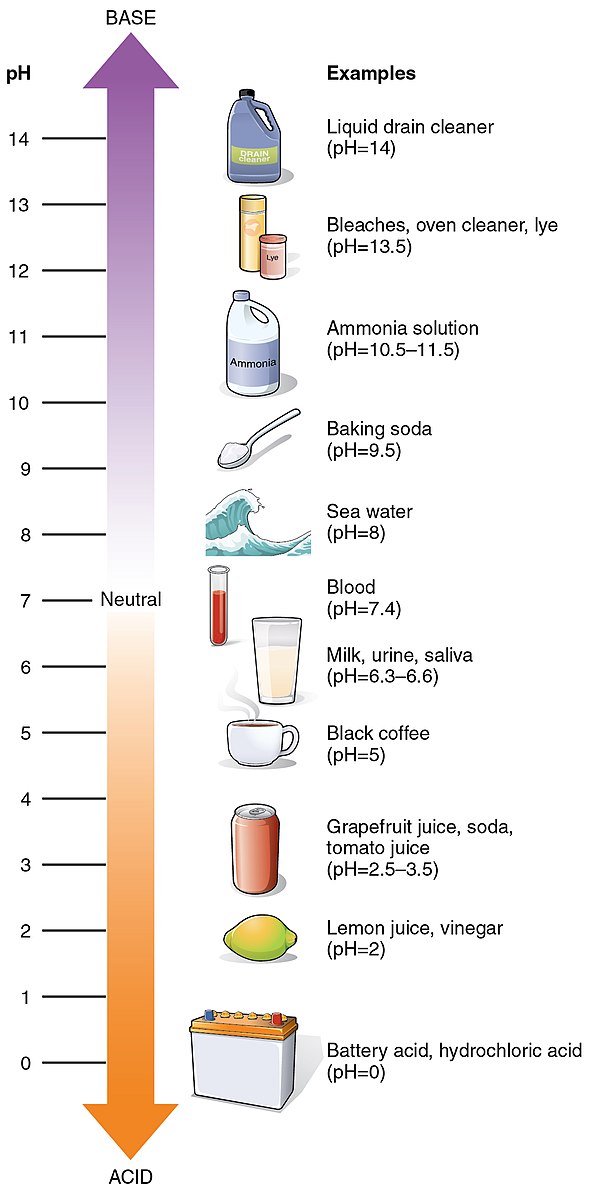

The pH of produced water, the water that comes to the surface during oil and gas production, is a crucial parameter that can significantly impact the overall quality and treatment of this wastewater. Typically, the pH of produced water ranges from 5.1 to 8.38, and it can contain a variety of contaminants, chemicals, and substances, including Total Dissolved Solids (TDS), Na, K, Ca, Mg, HCO3, Cl, SO4, and organic acids such as acetic acid.

Understanding the pH of Produced Water

The pH of produced water is often controlled by the CO2/bicarbonate system, and its solubility is directly proportional to temperature and pressure. This means that as the temperature and pressure of the produced water change, the pH can also fluctuate, making it a dynamic and complex parameter to manage.

Factors Affecting the pH of Produced Water

Several factors can influence the pH of produced water, including:

-

Geological Composition: The underlying geology of the oil or gas reservoir can contribute to the pH of the produced water, as the water interacts with the surrounding rock and minerals.

-

Injection Fluids: The chemicals and fluids used during the oil or gas extraction process, such as drilling muds, fracturing fluids, and scale inhibitors, can also affect the pH of the produced water.

-

Microbial Activity: Certain microorganisms present in the produced water can metabolize organic compounds, producing acids or bases that can alter the pH.

-

Temperature and Pressure: As mentioned earlier, changes in temperature and pressure can directly impact the solubility and speciation of the various ions and compounds in the produced water, affecting the pH.

Treating the pH of Produced Water

Image source: OpenStax College

Image source: OpenStax College

To manage the pH of produced water, various treatment methods can be employed, depending on the specific characteristics of the wastewater and the desired outcome.

Chemical Coagulation and Precipitation

One common approach is the use of chemical coagulants, such as ferric chloride or aluminum chloride, which can provide Fe(III) or Al(III) ions to remove hardness, COD, and turbidity from the produced water. This process can also help to adjust the pH to the desired level. However, this method requires the handling of larger amounts of chemicals and sludge, which can be a challenge for DIY users.

Desalination Techniques

Desalination technologies, such as reverse osmosis (RO) or membrane distillation, can be used to remove dissolved salts and other contaminants from produced water, which can help to stabilize the pH. These methods are particularly effective for high-salinity produced water, but they can be energy-intensive and may require pre-treatment steps to remove suspended solids and other impurities.

Biological Processes

Biological treatment methods, such as aerobic or anaerobic digestion, can also be used to manage the pH of produced water. These processes leverage the metabolic activities of microorganisms to break down organic compounds, which can help to neutralize the pH. However, these methods may require more complex system design and longer treatment times.

Mobile Water Treatment Devices

For DIY users, mobile water treatment devices can be a convenient and effective solution for managing the pH of produced water. These compact, self-contained units can treat up to 26,000 barrels (4,100 m3) of produced water per day with low energy consumption. They can reduce TDS, TSS, and turbidity while bringing the pH to the desired level, making them a versatile option for on-site treatment.

Monitoring and Maintaining the pH of Produced Water

Continuous monitoring and adjustment of the pH of produced water are essential to ensure the effectiveness of the treatment process and to prevent potential issues, such as corrosion, scaling, or the release of harmful substances.

Monitoring Techniques

Various techniques can be used to monitor the pH of produced water, including:

-

pH Meters: Handheld or in-line pH meters can provide real-time measurements of the pH, allowing for quick adjustments to the treatment process.

-

Titration: Laboratory-based titration methods can provide more accurate pH measurements, but they may require more time and specialized equipment.

-

Automated Monitoring Systems: Some mobile water treatment devices come equipped with integrated monitoring systems that continuously track the pH and other water quality parameters, enabling remote adjustments and optimization.

Maintaining the Desired pH

To maintain the desired pH of the treated produced water, users may need to adjust the dosage of chemical coagulants or the operating parameters of the treatment system. This may involve fine-tuning the pH setpoint, monitoring the system’s performance, and making necessary adjustments to ensure the water meets the required pH specifications.

By understanding the pH of produced water and implementing appropriate treatment methods, users can effectively manage this critical parameter and ensure the safe and responsible disposal or reuse of this valuable resource.