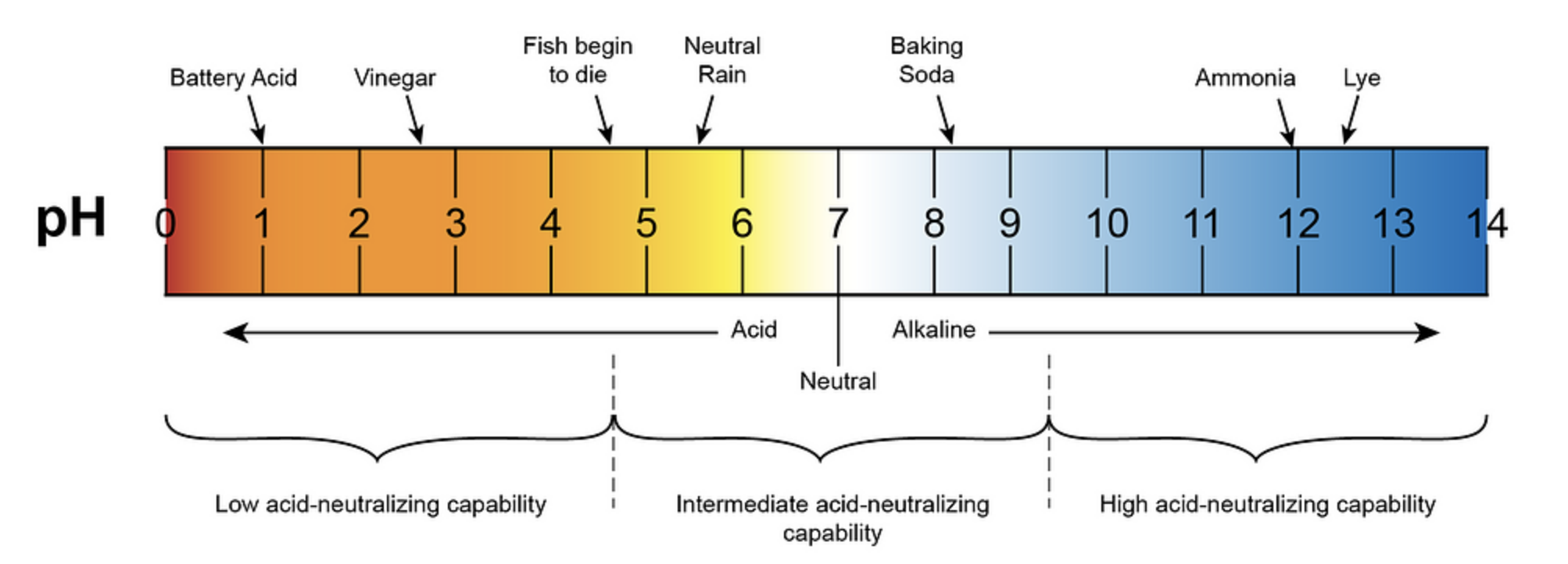

The pH value of oily water is a crucial parameter to consider, especially in industrial settings where wastewater treatment is essential. Proper pH control is vital for effective oil removal, preventing microorganism proliferation, and maintaining the quality of the treated water.

Understanding the pH Range for Oily Water Treatment

The typical pH range for oily water treatment falls between 7-9. This pH range is essential for the most common form of oil recovery and removal, which is pH adjustment with oil skimming. By lowering the pH with sulfuric acid, the process destabilizes emulsified oils and protonates slightly acidic oils, allowing for easier separation of the oils from the wastewater.

Oil Skimming and pH Adjustment

The oil skimming process involves lowering the pH to facilitate the separation of oils from the wastewater. Once the oils are free, an oil skimmer can remove the oil layer for recycling or disposal. However, this process requires the use of strong acids, which necessitates proper personal protective equipment (PPE) and training for operators to ensure safety.

After the oil removal, the wastewater will require the addition of hydroxides to raise the pH back to acceptable discharge ranges. If the skimmer is not sized properly or the tank does not have adequate still space, oil may remain in the wastewater, requiring additional treatment before the oil can be sent for recycling.

Alternative Oily Water Treatment Methods

Coalescing oil water separators are another method used in oily water treatment. These separators use Stokes’ Law to force oil droplets together, making them big enough to separate from the water and drain out of the units. However, emulsified oils of less than 0.5 microns will not separate using coalescing technology.

Chemical treatment is also an option, using demulsifiers that neutralize the stabilizing effect of emulsifying agents to break emulsified water/oil blends. These demulsifiers work best at a pH range between 7-9.

Biological treatment, such as using bacteria that produce lipase enzymes, can also be effective in degrading high levels of oil in oily water. These bacteria use oxygen for respiration and the hydrocarbons in oil as a food source.

pH Control in Hydraulic Fluid

When it comes to pH control in hydraulic fluid, fresh oil typically has a pH of 10.0, and a pH of 9.0 to 11.0 is appropriate. When the pH falls below 9.0, deterioration starts, with the lower the pH value, the more degradation progresses.

The Impact of pH on Oxidative Stability

In the case of an oil-water system, the oxidative stability in oil decreases significantly as the pH of the mixture of NaOH and HCl increases from 1 to 13. However, when using a buffer solution, the oxidative stabilities of oils are in the order of pH 4 = 7 > 10. This difference may be due to the difference in rates of proton release from acidic compounds in buffer solution.

Importance of pH Control in Oily Water Treatment

pH control is crucial in oily water treatment to prevent the proliferation of microorganisms that can decay oil and cause processing defects. High pH can also cause skin irritation, leading to dermatitis. Therefore, managing pH within the appropriate threshold is essential for maintaining the quality of oily water and preventing potential health hazards.

Conclusion

In summary, pH adjustment with oil skimming, coalescing oil water separators, chemical treatment, and biological treatment are all effective methods for treating oily water. Proper pH control is crucial to prevent the proliferation of microorganisms and maintain the quality of oily water. When testing pH in oil, it’s important to note that hydrocarbons like oil cannot be acidic without water present, and diluting the oil with water and shaking the two liquids vigorously may help indicate the presence of acidic compounds.

References:

- Finishing and Coating. (2020-07-29). Is Oil a Problem for your Wastewater Treatment? Retrieved from https://finishingandcoating.com/index.php/wastewater/281-is-oil-a-problem-for-your-wastewater-treatment

- ATAGO CO.,LTD. (n.d.). pH Meter Data Book-Industrial Oil and Ph. Retrieved from https://www.atago.net/en/databook-ph_industrial-oil.php

- Kim, J. Y., Yi, B., Lee, C., & Lee, S. (2016). Effects of pH on the rates of lipid oxidation in oil–water system. Applied Biological Chemistry, 59, 157–161. https://doi.org/10.1007/s13765-015-0146-3

- Bob Is The Oil Guy. (2019-09-24). Testing pH in oil; possible? Retrieved from https://bobistheoilguy.com/forums/threads/testing-ph-in-oil-possible.315799/

- ScienceDirect. (n.d.). The Effect of pH value on Crude Oil and its Fractions Oil-water Interficial Tension. Retrieved from https://www.sciencedirect.com/science/article/pii/S1876610212001932