Low pH pasteurization juice requirements are critical for ensuring the safety and quality of acidic juices. These guidelines, set by regulatory bodies like the FDA, specify temperature-time combinations to achieve a 5-log reduction in harmful microorganisms. For juices with pH ≤ 4.6, pasteurization temperatures range from 160°F to 180°F (71.1°C to 82.2°C) with corresponding time intervals from 6 seconds to 0.3 seconds. Compliance with these standards is crucial for juice producers to meet food safety regulations.

What Are the Specific Low pH Juice Pasteurization Standards?

Low pH juices, classified as high-acid foods with a pH of 4.6 or lower, require less stringent pasteurization processes compared to low-acid foods. The FDA and other regulatory bodies have established specific guidelines for these juices to ensure their safety and quality. The primary focus is on eliminating pathogens of concern, including:

- Escherichia coli O157:H7

- Salmonella species

- Listeria monocytogenes

- Cryptosporidium parvum

These microorganisms pose significant health risks and must be effectively controlled through proper pasteurization techniques.

What Are the Precise Low pH Juice Temperature Requirements?

The temperature requirements for high-acid juices (pH ≤ 4.6) are designed to achieve a 5-log reduction of the most resistant microorganisms. Here’s a detailed breakdown of the recommended temperature-time combinations:

| Temperature | Time |

|---|---|

| 160°F (71.1°C) | 6 seconds |

| 165°F (73.9°C) | 2.8 seconds |

| 170°F (76.7°C) | 1.3 seconds |

| 175°F (79.4°C) | 0.6 seconds |

| 180°F (82.2°C) | 0.3 seconds |

These precise temperature requirements ensure that the juice undergoes sufficient thermal treatment to eliminate harmful pathogens while maintaining its quality and nutritional value.

What Are the Exact Low pH Pasteurization Time Guidelines?

The time-temperature combinations for low pH juice pasteurization are critical for ensuring microbiological safety. Let’s explore each combination in detail:

- 160°F (71.1°C) for 6 seconds:

- This is a widely recommended treatment condition, particularly in New York.

- It effectively achieves a 5-log reduction of E. coli O157:H7, Salmonella, and Listeria monocytogenes.

-

Provides a balance between pathogen reduction and preservation of juice quality.

-

165°F (73.9°C) for 2.8 seconds:

- Offers a shorter processing time while still meeting the 5-log reduction criteria.

-

Suitable for juices that may be more sensitive to prolonged heat exposure.

-

170°F (76.7°C) for 1.3 seconds:

- A higher temperature option with an even shorter processing time.

-

Ideal for continuous flow pasteurization systems with rapid heating capabilities.

-

175°F (79.4°C) for 0.6 seconds:

- Classified as a High-Temperature Short-Time (HTST) pasteurization method.

-

Minimizes thermal impact on juice flavor and nutritional components.

-

180°F (82.2°C) for 0.3 seconds:

- The highest temperature and shortest time combination in this range.

- Requires precise temperature control and rapid cooling to prevent over-processing.

These time guidelines, when paired with their corresponding temperatures, ensure that the juice receives adequate thermal treatment to eliminate pathogens while minimizing the impact on sensory and nutritional qualities.

What Are the Comprehensive Low pH Juice Safety Regulations?

The safety regulations for low pH juices are designed to protect public health and ensure product quality. Here’s a comprehensive overview of these regulations:

Compliance Standards

- FDA Regulations:

- Juices must comply with the FDA’s regulations outlined in 21 CFR Part 120.

- This regulation mandates a 5-log reduction of the most resistant microorganisms of public health significance.

-

Compliance can be achieved through pasteurization or other validated processes.

-

HACCP Implementation:

- Juice producers must implement Hazard Analysis and Critical Control Points (HACCP) systems.

- HACCP plans should identify potential hazards and establish critical control points for their prevention or elimination.

Safety Thresholds

- 5-Log Reduction Requirement:

- The pasteurization process must ensure a 5-log reduction of key pathogens.

- This reduction corresponds to a 99.999% decrease in the number of microorganisms.

-

Target pathogens include E. coli O157:H7, Salmonella, Listeria monocytogenes, and Cryptosporidium parvum.

-

Critical Limits:

- Temperature and time combinations must be strictly adhered to.

- These limits are based on scientific validation studies for each specific juice type.

Testing Protocols

- Process Validation:

- Producers must validate their pasteurization process to ensure it meets the 5-log reduction requirement.

-

Validation typically involves:

- Microbiological testing before and after pasteurization

- Temperature and time monitoring during the process

- Use of surrogate organisms in some cases to simulate pathogen behavior

-

Continuous Monitoring:

- Critical parameters such as temperature and flow rate must be continuously monitored during production.

-

Automated systems with alarms are often used to ensure immediate response to any deviations.

-

Record Keeping:

- Detailed records of pasteurization parameters must be maintained.

-

These records should be readily available for regulatory inspections.

-

Periodic Verification:

- Regular testing of finished products to verify the effectiveness of the pasteurization process.

- This may include both microbiological and chemical analyses.

How Do Low pH Juice Requirements Differ from Other Juice Types?

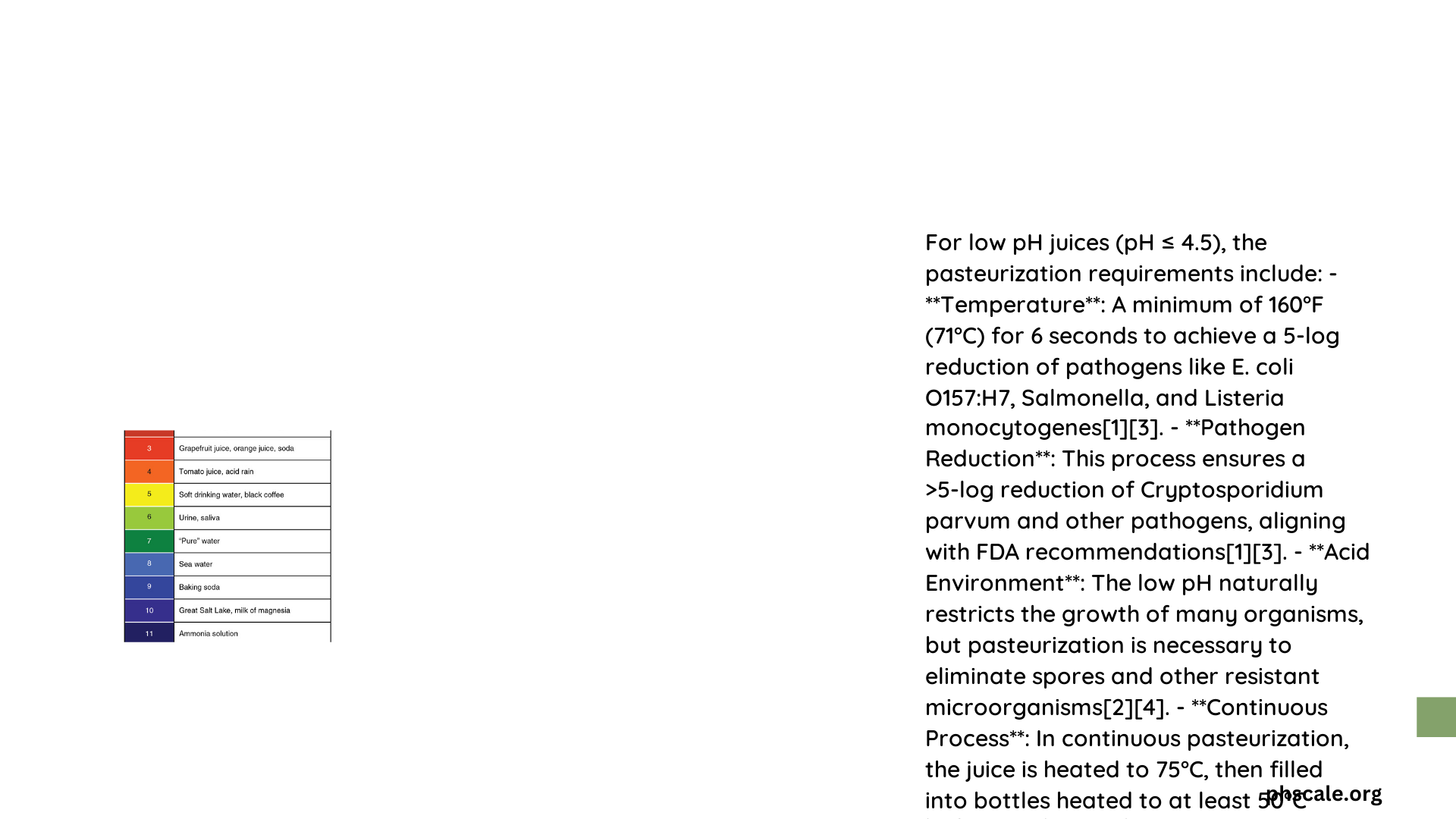

Low pH juices have distinct pasteurization requirements compared to other juice types due to their acidic nature. Here’s a comparison:

- Low pH Juices (pH ≤ 4.6):

- Require less intense heat treatment due to the inhibitory effect of acidity on bacterial growth.

- Typically pasteurized at temperatures between 160°F and 180°F (71.1°C to 82.2°C) for short durations.

-

Examples include citrus juices, apple juice, and most berry juices.

-

High pH Juices (pH > 4.6):

- Require more stringent pasteurization conditions due to the potential for growth of spore-forming bacteria.

- Often pasteurized at higher temperatures or for longer durations.

- May require additional preservation methods such as refrigeration or aseptic packaging.

-

Examples include carrot juice and some vegetable blends.

-

Shelf-Stable Juices:

- Regardless of pH, juices intended for shelf-stability undergo more intense thermal processing.

- Often use Ultra-High Temperature (UHT) processing, which involves temperatures above 275°F (135°C) for a few seconds.

This differentiation in pasteurization requirements highlights the importance of understanding the specific characteristics of each juice type to ensure appropriate safety measures are applied.

What Are the Key Challenges in Meeting Low pH Pasteurization Juice Requirements?

Meeting low pH pasteurization juice requirements presents several challenges for producers:

- Balancing Safety and Quality:

- Achieving the required 5-log reduction while maintaining the juice’s sensory and nutritional qualities.

-

Over-processing can lead to undesirable changes in flavor, color, and vitamin content.

-

Process Control Precision:

- Maintaining exact temperature-time combinations throughout the pasteurization process.

-

Requires sophisticated equipment and monitoring systems.

-

Product Variability:

- Different juice types and even batches of the same juice may have slight variations in pH and sugar content.

-

These variations can affect the efficacy of the pasteurization process.

-

Validation and Verification:

- Demonstrating that the chosen pasteurization parameters consistently achieve the required pathogen reduction.

-

Ongoing verification to ensure the process remains effective over time.

-

Regulatory Compliance:

- Keeping up with evolving food safety regulations and guidelines.

-

Implementing and documenting HACCP plans effectively.

-

Equipment Maintenance:

- Ensuring pasteurization equipment is properly maintained and calibrated.

-

Preventing biofilm formation and other sources of contamination.

-

Cold Chain Management:

- For refrigerated juices, maintaining proper temperature control throughout distribution and retail.

Addressing these challenges requires a comprehensive approach to juice production, combining scientific understanding, technological solutions, and rigorous quality control measures.

How Can Producers Ensure Compliance with Low pH Pasteurization Juice Requirements?

To ensure compliance with low pH pasteurization juice requirements, producers should follow these best practices:

- Implement a Robust HACCP Plan:

- Develop a comprehensive Hazard Analysis and Critical Control Points (HACCP) plan.

- Identify all potential hazards and establish critical control points.

-

Regularly review and update the plan as needed.

-

Invest in Reliable Pasteurization Equipment:

- Use pasteurization systems designed for precise temperature control.

- Implement continuous flow systems with rapid heating and cooling capabilities.

-

Ensure equipment is properly sized for production volume.

-

Conduct Regular Process Validations:

- Perform initial validation studies to confirm the effectiveness of pasteurization parameters.

- Repeat validations when there are changes in juice formulation or processing conditions.

-

Use accredited laboratories for microbiological testing.

-

Establish a Comprehensive Monitoring System:

- Install automated temperature and flow rate monitoring devices.

- Implement alarm systems to alert operators of any deviations from critical limits.

-

Maintain detailed records of all monitoring activities.

-

Train Personnel Thoroughly:

- Provide comprehensive training on food safety principles and HACCP procedures.

- Ensure operators understand the importance of adhering to pasteurization parameters.

-

Conduct regular refresher training sessions.

-

Perform Regular Equipment Maintenance:

- Establish a preventive maintenance schedule for all pasteurization equipment.

- Calibrate temperature sensors and other critical instruments regularly.

-

Keep detailed maintenance logs.

-

Conduct Periodic Third-Party Audits:

- Engage independent auditors to assess compliance with regulatory requirements.

-

Address any identified non-conformities promptly.

-

Stay Informed on Regulatory Updates:

- Regularly review FDA guidelines and industry best practices.

-

Participate in industry associations and attend relevant conferences.

-

Implement a Traceability System:

- Establish a system to track ingredients and finished products throughout the supply chain.

-

Conduct mock recalls to test the effectiveness of the traceability system.

-

Maintain Open Communication with Regulatory Agencies:

- Establish a good relationship with local food safety inspectors.

- Seek clarification on regulatory requirements when needed.

By following these practices, juice producers can ensure consistent compliance with low pH pasteurization requirements, thereby safeguarding public health and maintaining product quality.